To be a top digital presses supplier and add honor to world's manufacturing.

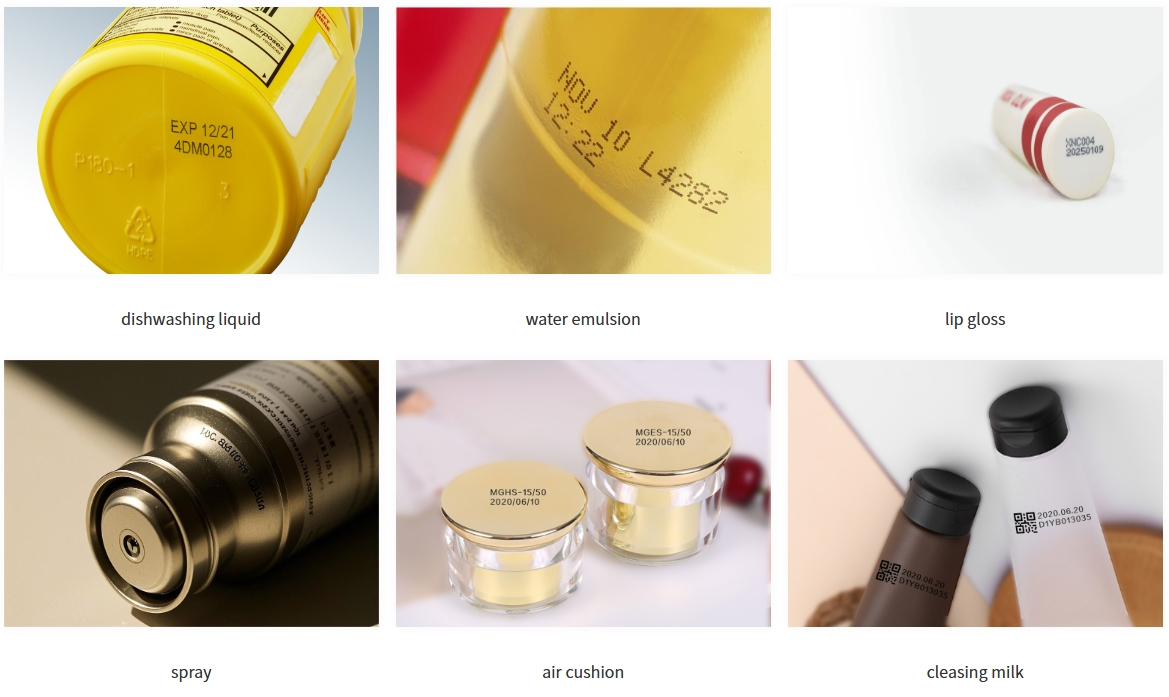

Daily Chemical

The cosmetics and care industry has regulations that require clear production and expiration dates to help avoid adverse reactions such as allergies after use. Related brand trademarks can be printed on packaging to convey brand information. Combining anti-counterfeiting traceability codes can effectively prevent brand counterfeiting and protect brand image. We offer a complete solution to print clear content, anti migration, and friction resistant reliability marks on uneven or smooth surfaces of various cosmetic care products.

Food and Beverage

The packaging environment for food and beverage is diverse and complex, requiring professional and adaptable coding and labeling techniques. Therefore, we provide reliable labeling and coding solutions for various food industries. Various types of food packaging materials can be printed with text, production dates, quality assurance dates, and other information. Even in cold or humid, high temperature or dry harsh environments, our small character inkjet printer series and hot foam inkjet printer series can still work stably and guarantee high performance under various harsh production conditions. High quality printing effect.

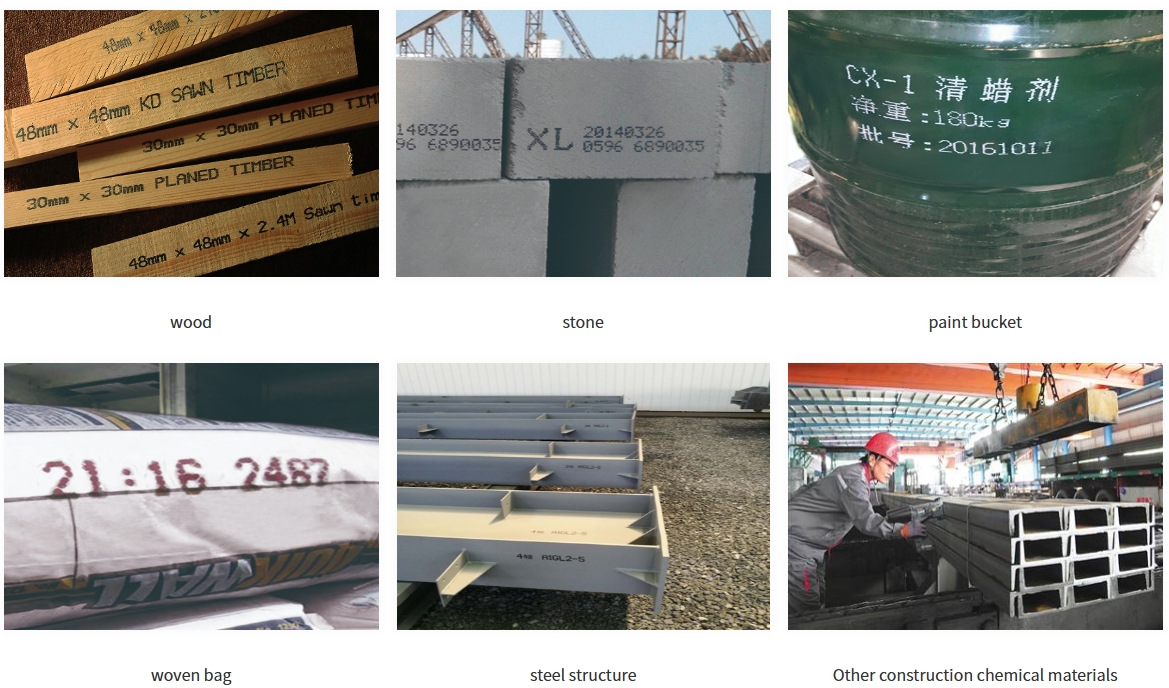

Construction Chemical

The construction industry needs to work continuously in high temperature, dusty, and humid environments, so we provide a complete set of reliable printing and marking solutions. Our inkjet printers have a sturdy dustproof and waterproof protection level, which can effectively prevent dust and water vapor from entering and maintain stable working conditions in dusty or high humidity production environments. Even in harsh environments such as high temperatures, our inkjet printers can operate continuously and stably to ensure the sustainability of production.

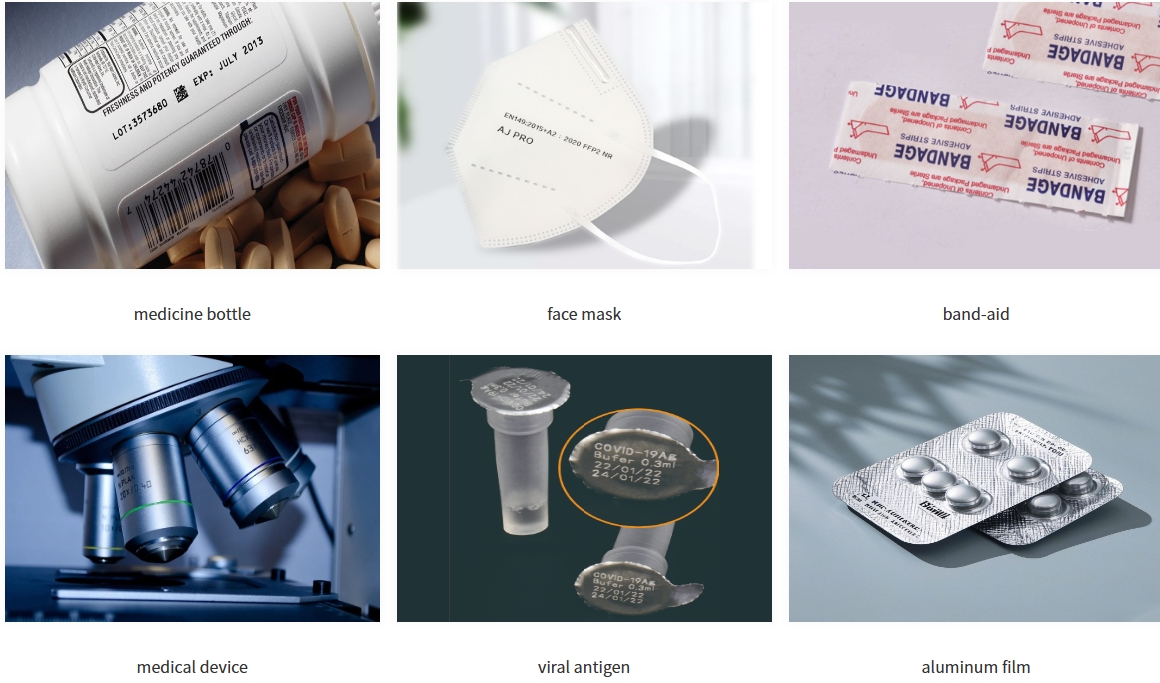

Medical

In the medical industry, the implementation of drug GMP requirements has strict standards for the production equipment, production processes, and testing systems of enterprises. Comply with UDI medical device labeling requirements and comply with the laws and regulations of the exporting country. We provide printing and marking solutions that meet standard requirements. In the working process of our coding equipment, it is stable, clean and tidy, meeting the special needs of the production environment in the medical industry. Encode and trace drugs to achieve process inquiry, logistics tracking, and product anti-counterfeiting, ensuring that the quality of the final product meets legal requirements.

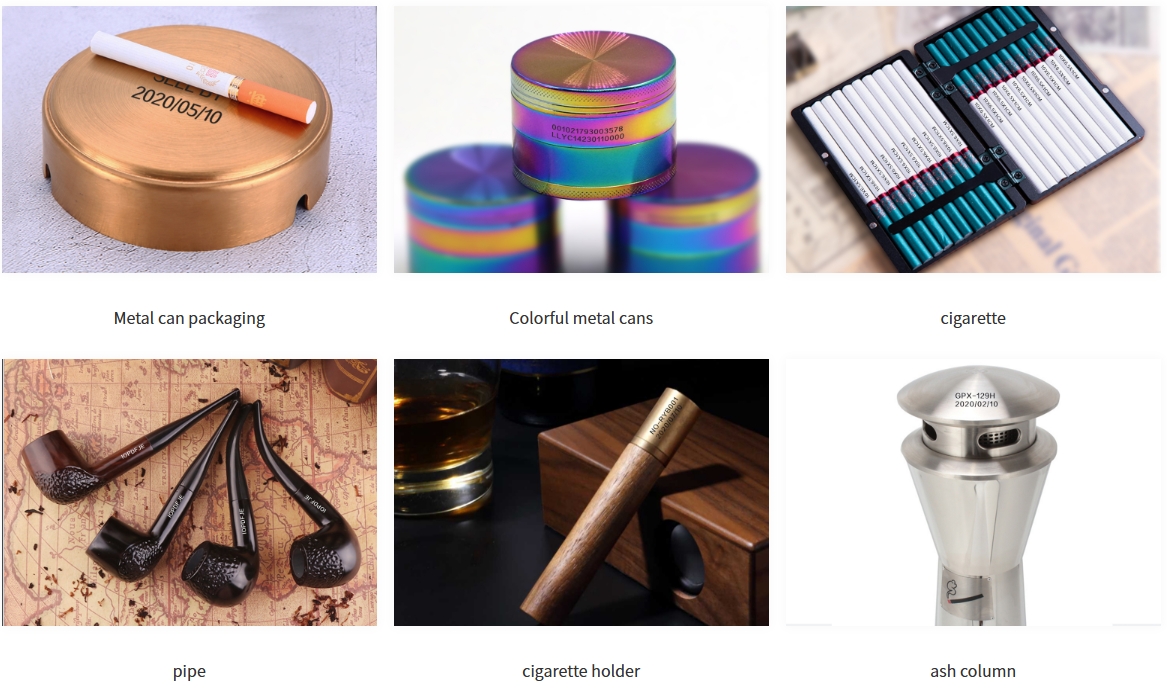

Tobacco

The tobacco industry operates under strict global regulatory standards and requires high-precision coding and labeling to ensure compliance and traceability. These regulations require detailed labels to be affixed to packaging at all levels (including first, second, and third level) to meet various requirements such as stamp duty, health warnings, and batch traceability. The coding equipment in this field must also support regulatory compliance: mandatory coding requirements include clear and durable stamp duty stamps, unique identifiers, and regulatory information. This ensures the authenticity of the product, compliance with directives such as the EU Tobacco Products Directive (TPD).

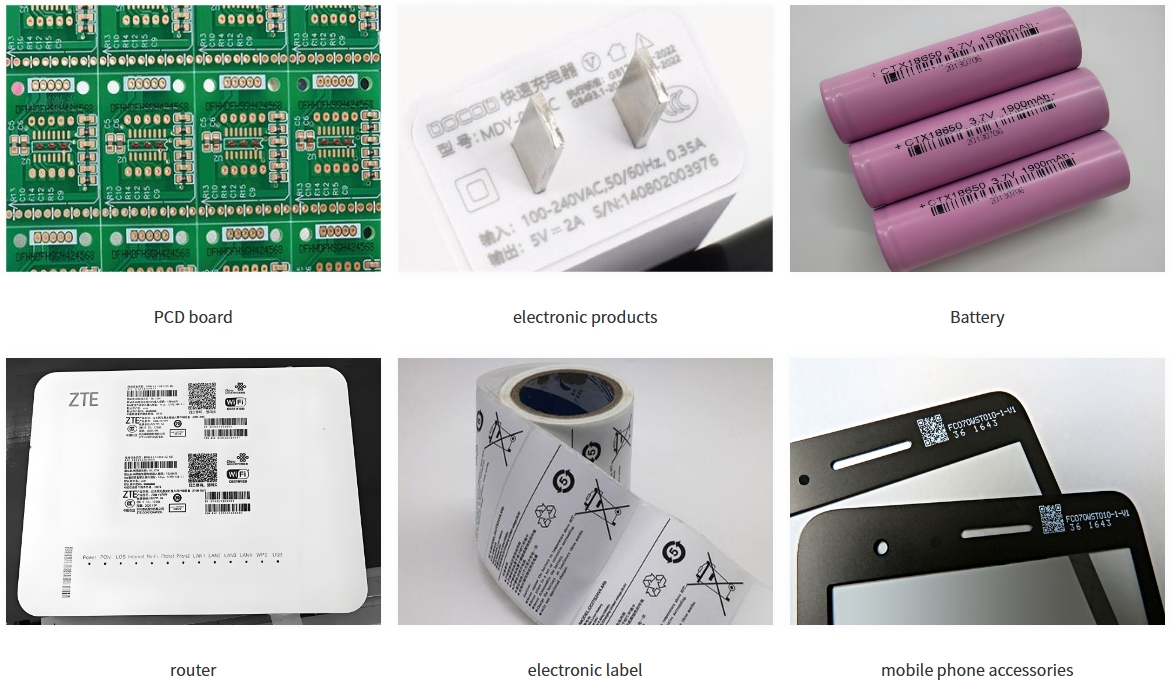

Electronic Components

Electronic components have small size and high precision, requiring extremely high precision and resolution for printing. Clear and accurate markings such as product model, serial number, production date, etc. need to be printed on tiny surfaces. Electronic products are updated and replaced quickly, with multiple production batches. Printing equipment needs to have the ability to quickly switch printing content and parameters to adapt to frequent production changes. The electronics industry has high requirements for the cleanliness of the production environment, and printing equipment needs to have good sealing and dust-proof performance to prevent dust and impurities from affecting product quality.

Automotive and Aviation

Automotive and aviation components have extremely strict requirements for product quality and traceability. The printing content should include product model, serial number, batch number, production date, traceability code, etc., in order to achieve full lifecycle management and quality traceability of the components. The materials of components are diverse, such as metal, plastic, ceramics, etc., which require high adaptability to printing equipment and ink. It is necessary to achieve firm and clear printing effects on different material surfaces. The production environment is complex, and some components need to work in special environments such as high temperature, high pressure, and high humidity.

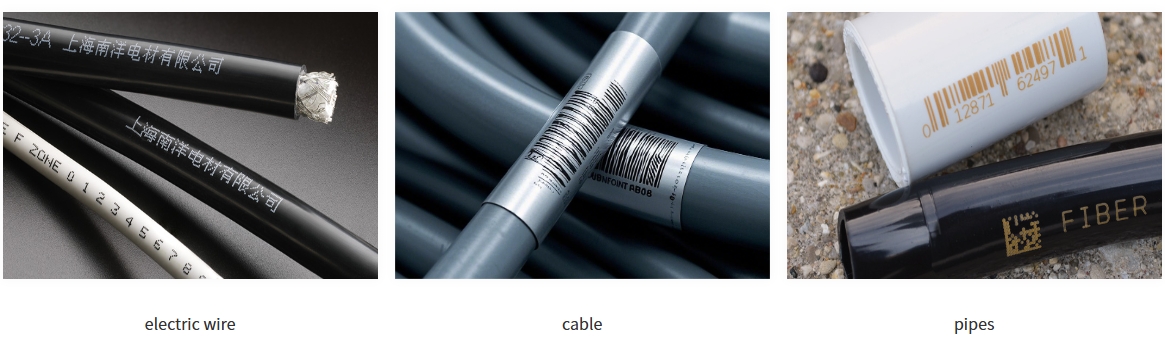

Wire, Cable and Pipe

Wire, cable, and pipe products are usually in the form of long strips and require continuous printing during the production process. The printing equipment needs to have continuous and stable printing capabilities. There are many contents of product identification, including product model, specifications, length, production date, execution standards, etc. The printed information should be clear, accurate, and not easily worn. The production speed is fast, requiring printing equipment to respond quickly and achieve precise printing on high-speed production lines. Different materials of wires, cables, and pipes (such as plastic, rubber, metal, etc.) have different requirements for printing ink and processes.